The TRIO Story

From it’s very humble beginning back in 1978 ,The TRIO Group has built a reputable position in the premium leather goods industry. The group has grown by leaps and bounds, and continue’s to lead as a fine leather goods manufacturer and exporter in the global market.

TRIO Group operates under the two premium leather manufacturing companies– ‘TRIO Trend Exports’ & ‘Yamai Fashions Private Limited’. We manufacture a wide array of products ranging from all types of bags, wallets & purses to leather goods for smart & e-products.

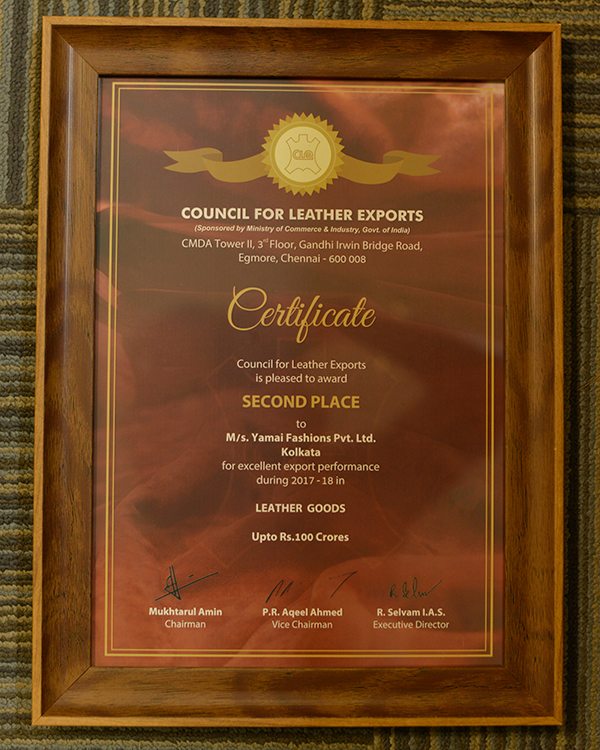

TRIO’s sustained success and guaranteed future as a premium leather goods manufacturer, is owed to our dedication to high-quality standards. We are an SA 8000 SEDEX SMETA compliant company which has been honoured with several awards from the Council of Leather Exports, India .

Infrastructure

Modern & Advanced Infrastructure

TRIO Group has one of the most advanced infrastructures in the leather goods industry.12+ Facilities

TRIO has 12 highly advanced facilities to manufacture premium leather and non leather, bags ,wallets , purses , travel goods and other small accessories.Expansion Facility Available

Keeping scalability in consideration, a sprawling manufacturing facility has been constructed with a floor space of more than 144,000 sq.ft.

Production Capacity / Annum

| PRODCUTS | CAPACITY/ANNUM | EXPANDABLE CAPACITY / ANNUM |

|---|---|---|

| BAGS | 750,000 pcs | 100,000 pcs |

| SMALL LEATHER GOODS | 750,000 pcs | 150,000 pcs |

International Standard Warehouses with Dehumidifying Chambers

TRIO is equipped with two international standard warehouses, with dehumidifying chambers to enable quick packing, storing and dispatch while maintaining optimum product quality.- Modern Machines and Equipment

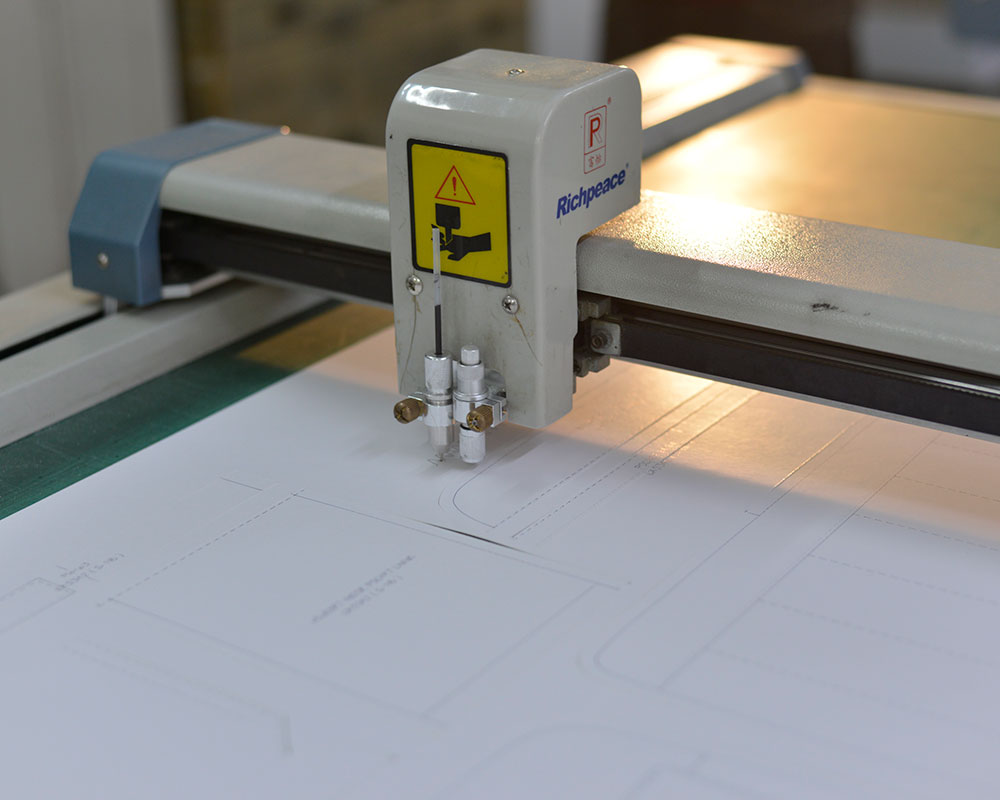

All machines and equipment in our leather goods factories are acquired from leading manufacturers, like Durkopp, Adler, OMAC, ATOM, Camoga, Juki, etc. These include automatic sewing machines, computerized pattern stitching machines, screen printing machines, automatic embossing machines, skiving machines, clicking machines, auto gluing machines, zipper cutting machine, drying machine, auto edge painting machines and many more. Adhering to International Quality Standards

We strive to uphold production quality conforming to International standards. We ensure quality is the core, starting from sourcing to the final product.

Supply Chain

Strategic Sourcing

TRIO Group’s Sourcing has been a benchmark among Indian leather goods manufacturers through its strategic sourcing methods.Sourcing Compliant to International Standards

The team maintains a smart sourcing network for leather and non leather materials in both domestic & international markets, from India / Italy / Thailand / Turkey and Korea. All our leather and non leather variants are sourced in compliance with LWG, REACH and PROP65 standards.- Price Point Sourcing & New Item Sourcing

Price Point sourcing and new innovative item sourcing, as per latest trends are two main features that are highly prioritised at TRIO. Sustainable Green Sourcing Approach

We at TRIO, ensure that the sustainability benchmarks are responsibly met throughout our supply chain. Hence, we have evolved to responsible material sourcing policies, by procuring eco friendly and recycled materials, to make value added sustainable products.

Research & Development

120 Member Efficient Sampling Team for Quick Sampling

Our product development process is supported by a 120 member skilled sampling team, whose efforts ensure sampling completion in the shortest of durations, providing the finest of craftsmanship and unmatched quality.- Product Innovation as per Latest Trends

TRIO’s research team is specially assigned to innovate products , materials and concepts in alignment with the latest International trends and standards .

Client Servicing

- Effective Communication

At TRIO, we are dedicated to accurately communicating with our customers and providing them with timely information that facilitate informed decisions and amicable relationships. Customer Relationship Management Systems

Our customer service team shoulders Planning, production and logistical responsibilities and maintains Customer Relationship Management Systems through our IT system.- In Sync with the Latest Trends

Through regular workshops and evaluations, we ensure that this department has up-to-date knowledge of evolving tastes and preferences, material research and familiarity with the leather goods market trends.

Product Engineering

Technical Support Team

TRIO’s Product Engineering Department works as a technical support team to assess and analyse each product carefully before it goes to production, which bridges the gap between the development & production teams.Equipped with Modern Equipment

This department is equipped with state-of-the-art machinery, jigs & tools and works tirelessly in product engineering of each & every product before bulk production begins.

Total Quality Management

Quality is the core of our customer satisfaction

Our quality management system is focused on consistently meeting customer requirements and enhancing their satisfaction.

We have two core teams Quality Assurance (QA) and Quality Control (QC).

The QA team

The QA team is communicating with the customer and have the responsibility for the product until the start of production. It mainly focuses on the below features:

- Compliance

- Product risk assessments

- Leather and non leather material compliance and their approvals

- Product engineering

- Gold seal and sampling approval

- Product training and full handover to production

The QC team

This team takes over, once the product starts with production and has “eyes on” throughout its journey on the floor. It ensures the below points:

- Leather and cut components meet customer requirements

- QC reports are reviewed daily on each product throughout the duration of production

- Production meets the standards set by our customers

Quality Compliance

- International Testing Standards are followed for finished goods like Prop 65, CPSIA, China GB.

- All our leather and non leather variants are sourced in compliance with LWG, REACH and PROP65 standards.

- Use of in-house testing lab alongside testing carried out by established and reputed third-party testing houses for raw materials and finished products for compliance to customer standards.

- In-House Testing Lab

Our Internal Test Lab is equipped with machineries that performs leather, non-leather and finished product testing.

Quality Control Process

- We perform quality checks on all our incoming materials & at various stages of the manufacturing process from Leather cutting to finished products.

- Experienced Quality Inspectors conduct thorough checks on the finished leather products for aesthetics and functionality.

- AQL inspections are performed on the packed shipments before dispatch through the help of agencies like BUREAU VERITAS, INTERTEK and SGS.

- Three X-ray scanners are used to scan all the goods, piece by piece, before they are shipped as a safety measure to detect any hidden sharp metal parts.

Certifications & Affiliations

Recognitions & Awards

- CLE Award for 2nd position in All India Top Export Performance 2018

- Regional Top Export Performance 2018.

- Export Award for First place for Commendable Export Performance in Leather Goods for the year 2012.

- Top Exporter Award for the year 2010 – 2011 by ILPA.

- EPCES Export Award for Best EOU (MSME) in the Leather products for the year 2010-2011.

- EPCES (Export Promotion Council for EOUs and SEZ Units) Export Awards for Outstanding Export Performance during the year 2009-10.

- Export Award for First place for Commendable Export Performance in Leather Goods for the year 2009-2010

- Special Certificate of Merit from the National Productivity Council (MSME) in the Leather Goods category for the year 2008-2009

- Export Award for First place for Commendable Export Performance in Leather Goods for the year 2007-2008

- EPCES (Export Promotion Council for EOUs and SEZ Units) Export Awards for Outstanding Export Performance during the year 2007-08

- Merit Award for Commendable Export Performance for Leather Goods during 2005-06

- Export Award for Creditable Performance in Leather Product from the Union Minister for Commerce and Industries for the year 2004-2005.

- NSIC – D&B – SMERA Rating Certificate under SE 2A category. The Rating indicates the Group has High Financial Strength